Test benches for vacuum pumps

Test benches for liquid ring vacuum pumps

Test benches for decompressors and vane vacuum pumps

Compressor test benches

Vacuum test from -0.99 bar to 0 bar relative

Pressure testing up to 2 bar

Measures air flow rates from 100 to 66,000 Nl/min

Torque detection up to 1000 Nm

Pump power up to 100 KW

Drive with fixed electric motor at variable speed from 0 to 1600 RPM

Complete with piping and motorised valves for flow and pressure regulation

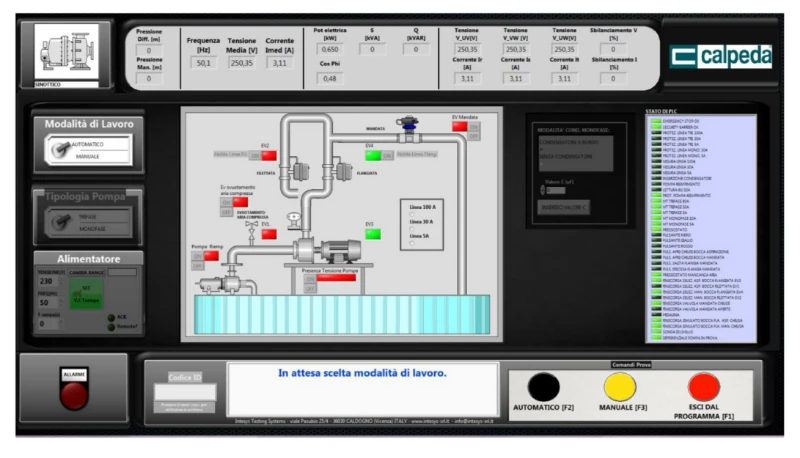

Control via PC and Intesys PumpTest Air acquisition software

Results in weight and volume values referred to cond environmental

(Optional) primary calibration circuit according to EN ISO 5167

Fan test benches

Test benches for fume hoods

Measures air flow rates from 120 to 1200 Nmc/h

Electrical parameter detection

Detection of environmental conditions: humidity, ambient temperature, atmospheric pressure

Analysis of the real-time behaviour of the fan and especially the fan load curve (Torque-RPM curve)

Vibration and friction detection and analysis

Direct determination of yield and losses

Fan power supply

Speed setting and verification for brushless fans

(for production line systems) Ground Continuity Verification

Our control and data acquisition software, developed in LabVIEW, efficiently manages the setup and analysis of test bench data. The manual test cycle involves the PC-controlled manual acquisition of data such as pressure, power, electric current and DC voltage. The operator controls the valves and servomechanisms during the test, ensuring complete supervision.

The automatic test cycle, based on preset data in the pump database, automatically adjusts valves and servomechanisms according to the selected pump code. The valve positions itself in a predefined manner, allowing accurate verification of data against sample values with programmable tolerances.

On-screen visualisation and data storage provide a detailed overview of performance during the test, with clear warnings of compliance or non-compliance. The database stores pump specifications and tolerances.

The reports generated include standard test bulletins, highlighting measured values and deviations from sample values. Wherever possible, range-prevalence graphs are included, providing a visual representation of the results. The software adapts to ISO 9906 standards, offering a comprehensive and efficient approach to pump test data management.

Discover more about PumpTest

INTESYS Srl

Sistemi di collaudo

Viale Pasubio, 25/4 – 36030

Caldogno (Vicenza)

tel: 0444 905440

fax 0444 1830 932

info@intesys-srl.it