Test bench for vertical multistage pumps

With and without motor up to 25 mc/h and 270 mca head.

Triple station bench for vertical multistage and horizontal pumps

up to 60 mc/h and 300 mca head and high-flow centrifugal pumps (260 mc/h) with manual connection

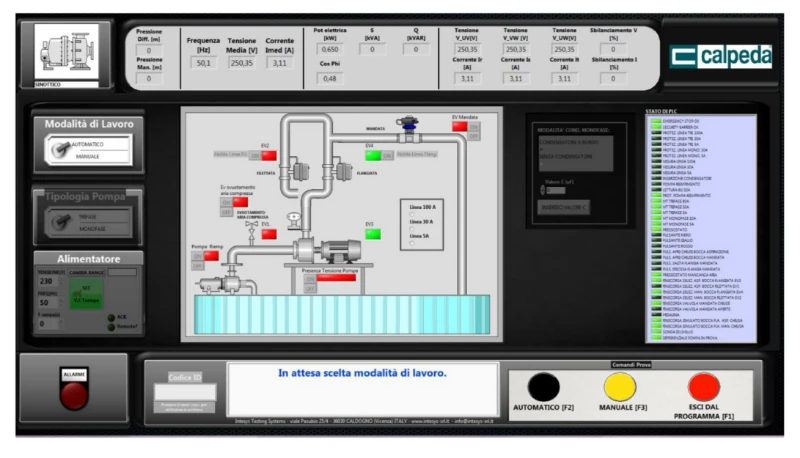

The bench consists of a tank and three independent stations for the simultaneous testing of electric pumps as per the subject.

Clamping and connecting are manual. Hydraulic and electrical test cycles are automatic as already indicated for the previous bench. The bench is also equipped with an inverter-controlled booster pump to create additional headroom for high-flow pumps. At the end, a graphical test report is printed and attached to each pump

Vertical multistage pumps with and without motor up to 25 mc/h and 270 mca head

Vertical multistage pumps with and without motor up to 80 mc/h and 300 mca head (see point 4 above)

Fully automatic computerised double-station test rig for horizontal electric pumps up to DN 40 and up to DN 100 (MEC80), for powers up to 10 hp

The bench, based on the code indicated at the beginning by the operator, automatically positions and connects the hydraulic fittings to the threaded delivery and suction ports of the pump. Subsequently, the bench performs an electrical safety test according to regulations and then a hydraulic and electrical functional test cycle via the control of two automatic proportional valves that vary the pump flow rate. The bench also carries out tests at 60 Hz by means of a special converter-variator unit that also allows the voltage to be varied continuously from 0 to 500 Vac. At the end, a visual indication of the test result is given and, if necessary, a graphic test report is printed to be attached to the pump. The total test time is max. 1.5 minutes.

fino a 2” (MEC63 MEC71)

Automatic end-of-line test bench. The bench is equipped with a PLC system and operator terminal. Based on the code given at the beginning by the operator, the bench automatically positions and connects the hydraulic connections to the threaded delivery and suction ports of the pump. Next, the bench performs an electrical safety test according to regulations and then a hydraulic and electrical functional test cycle via the control of an automatic proportional valve. At the end, a panel printer provides a swipe with all the data acquired and the result of the test. The bench is also equipped with a 60 Hz converter unit and a manual variac for adjusting the pump supply voltage from 0 to 500 Vac

Testing room for pumps

prototype

up to 7000 l/min

Provision of specifications and hydraulic-mechanical engineering, instrumentation and software for Pulpito Pedrollo SP2 – 2.jpgdata acquisition, servomechanism control, printing of bulletins, storage of results. The detailed mechanical design, mechanics and hydraulics were carried out by partner companies. The software enables the testing and management of archived data according to regulations. (see Intesys PumpTest Software (pdf, 3. 14 MB)

Testing room for pumps

Submerged

On-board drive motor)

Computerised automatic test bench for measuring hydraulic quantities (flow rate up to 80 mc/h, pressure up to 50 bar), torque (using a torque transducer from 6 to 200 Nm) and rotational speed (up to 3800 RPM). A variable speed DC motor drives the pump under test. A torque transducer placed between the motor axis and the pump axis, instantaneously detects the torque and the pump

The tank has one compartment for supporting, securing and connecting the pump to the torque-motor shaft and another for holding the water required to submerge the pump after connection.

The software is equipped with a database of pump nameplate data and a database of tests performed. At the end of testing, a test report is issued and attached to each pump.

Prototype test tank for various types of pumps

suitable for repair shops

AISI 316 stainless steel tank for testing circulators, surface pumps, submersible pumps, maximum flow rate 1200 litres/min, minimum flow rate 15 litres/min, maximum head 250 mca.

manual shut-off valves and control valves that can be replaced by automatic valves

flow meters

pressure sensors on both discharge and suction

rack cabinet with instrumentation and data acquisition system for acquiring and storing electro-hydraulic tests

Test bench for horizontal and submersible grinder pumps

Clamping and drive bench (cuplometer to torque transducer) for horizontal grinder pumps up to 75 KW, with on-board electric motor and speed control system up to 4000 RPM

Tank and hydraulic system for flow rate and head detection range 3 – 1500 mc/h

75 KW – 2 mod.JPGSystem with tank and vacuum pump for vacuum testing (NPSH)

Control system (Intesys PumpTEST brochure, pdf 1.2 MB) for measuring torque (via bench-mounted torque transducer), flow rate, head, NPSH, electrical quantities (pumps with their own electric motor), hydraulic efficiency, pump speed regulation.

Standard 20′ “tank” container with walk-on grating for testing surface pumps and submersible/submersible pumps

Standard 20” storage container

Standard 20 ‘Control’ container equipped with piping, valves, flow, pressure and level sensors

Power supply panel

Rack with control and data acquisition system and Intesys PumpTEST software

Variable voltage and frequency power supply unit

Containerised mobile test rig for centrifugal surface pumps and submersible/submersible pumps

suitable for repair shops

Our control and data acquisition software, developed in LabVIEW, efficiently manages the setup and analysis of test bench data. The manual test cycle involves the PC-controlled manual acquisition of data such as pressure, power, electric current and DC voltage. The operator controls the valves and servomechanisms during the test, ensuring complete supervision.

The automatic test cycle, based on preset data in the pump database, automatically adjusts valves and servomechanisms according to the selected pump code. The valve positions itself in a predefined manner, allowing accurate verification of data against sample values with programmable tolerances.

On-screen visualisation and data storage provide a detailed overview of performance during the test, with clear warnings of compliance or non-compliance. The database stores pump specifications and tolerances.

The reports generated include standard test bulletins, highlighting measured values and deviations from sample values. Wherever possible, range-prevalence graphs are included, providing a visual representation of the results. The software adapts to ISO 9906 standards, offering a comprehensive and efficient approach to pump test data management.

Discover more about PumpTest

INTESYS Srl

Sistemi di collaudo

Viale Pasubio, 25/4 – 36030

Caldogno (Vicenza)

tel: 0444 905440

fax 0444 1830 932

info@intesys-srl.it