They detect the electrical/dynamic characteristics and temperature test of asynchronous, single-phase and three-phase, brushless and DC electric motors.

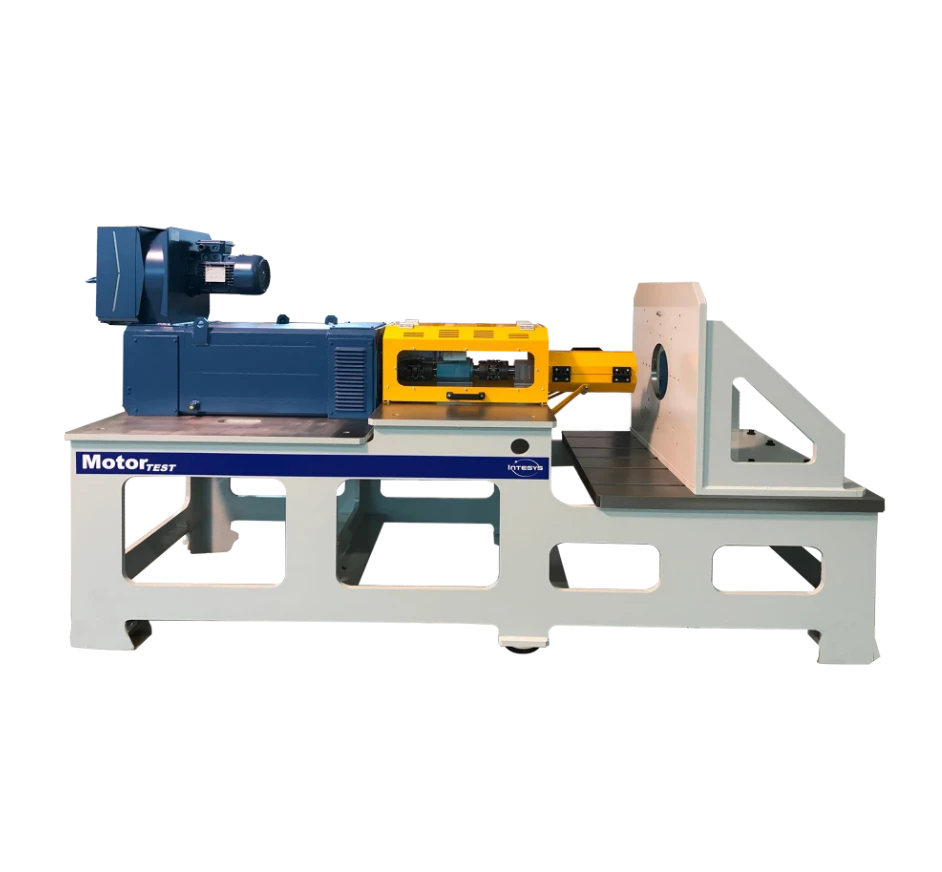

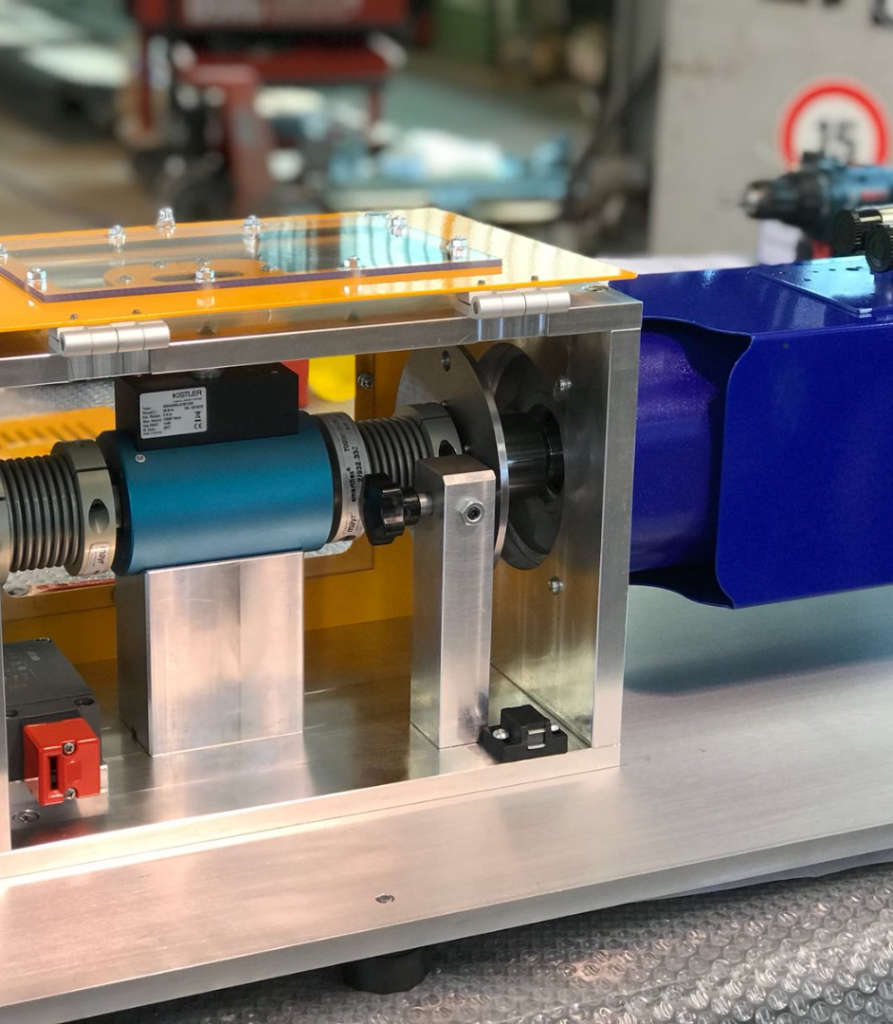

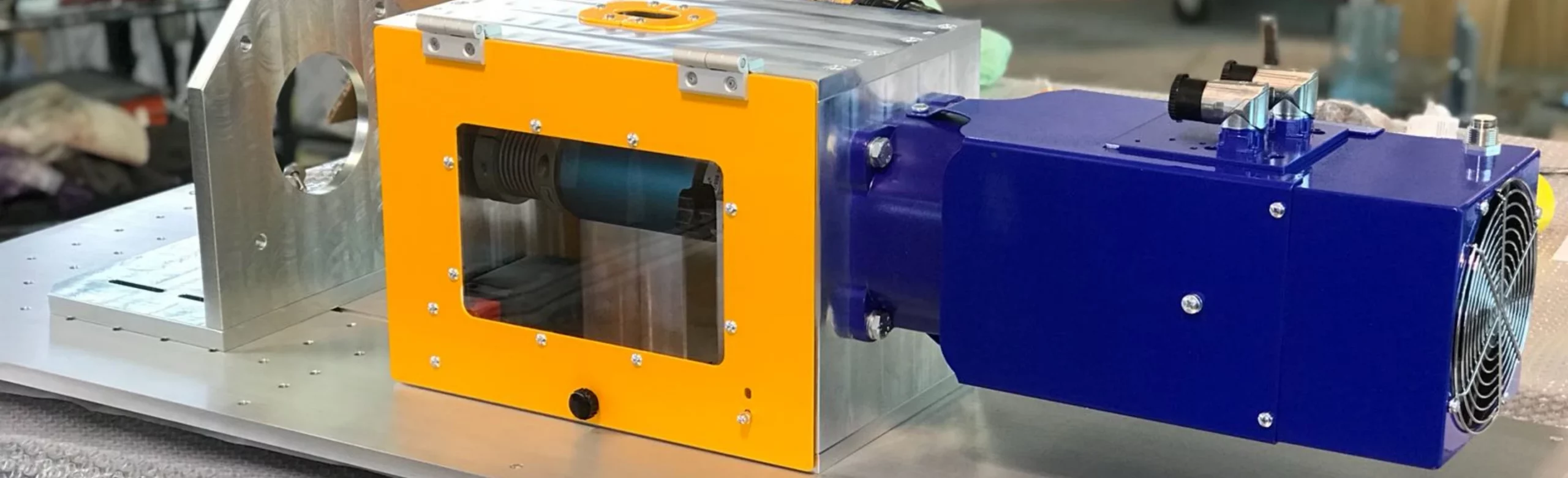

These are brake banks that use an electric motor controlled by a frequency converter (inverter) as the braking element instead of an eddy-current or magnetic powder brake.

The motor+converter transforms the mechanical energy of the motor under test into electrical energy that can be returned to the grid or reused within the company’s own power supply or by a variable frequency power supply. Dynamic brakes are the best solution for every type of electric motor

For automotive AC and DC motors with variable speed up to 10000 RPM and power up to 50 KW

In the context of the automotive and shipbuilding industries, we design and build test systems for endothermic engines, adapting them to the specific needs of our customers; We offer complete solutions, ranging from the creation of end-of-line test benches to the design of dedicated systems for research and development. Our range of services includes the overhaul of mechanical and electronic components on existing benches, the installation of new data acquisition systems and transducers, and the updating or replacement of management software.

Our commitment to manufacturing is based on proven experience and the use of state-of-the-art technology, such as active or passive dynamometers and advanced switchgear. These tools allow complete test monitoring, including crucial aspects such as power and exhaust gas analysis. In addition, we provide complete solutions for combustion air management, extraction and ventilation systems, cooling towers and all necessary safety and soundproofing measures for the work area. Our philosophy is centred on creating efficient and safe test environments, where accuracy and reliability are at the heart of every solution we offer.

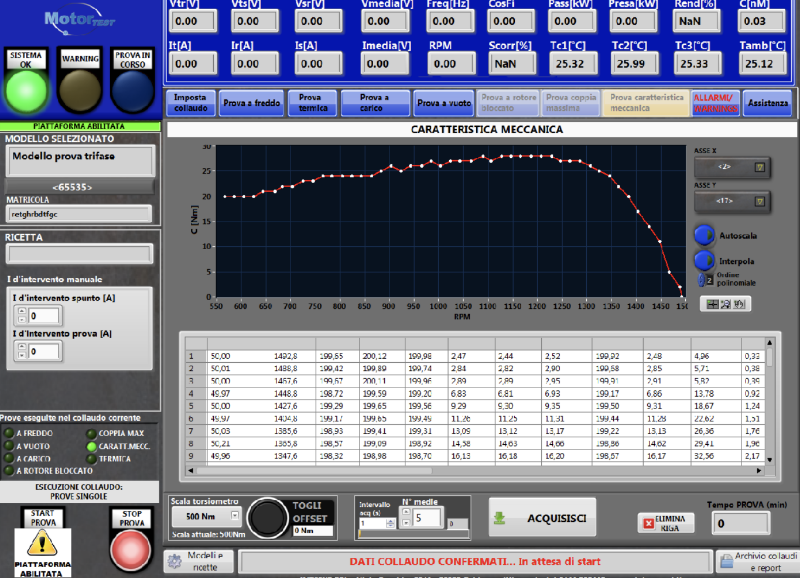

MotorTest Software

LabVIEW®

MotorTEST LabVIEW® is software that enables the complete characterisation of electric motors on motor brake benches and is compatible with a wide range of market-standard control/data acquisition systems and instrumentation

Detectable quantities:

motor speed, torque, power output, voltages, currents, absorbed and apparent power, power factor, efficiency, slip, mains frequency, motor winding resistances, temperatures

Motor and brake registration data archive:

database in MS Access format into which the operator enters both the test bench settings and the registration data of the engines to be tested; The parameters selected before testing will automatically set the inverter configuration of the braking motor and the inverter configuration of the motor to be tested (high-frequency motors)

Discover more of MotorTest

INTESYS Srl

Sistemi di collaudo

Viale Pasubio, 25/4 – 36030

Caldogno (Vicenza)

tel: 0444 905440

fax 0444 1830 932

info@intesys-srl.it